A. B. Carter, Inc. is a major supplier of spindle tapes and drive belts, light weight conveyor belts and pulling straps for almost any textile machine application. These products can be supplied “pre-assembled” to your specifications or may be sold in bulk with optional adhesive and bonding equipment for in-plant customer preparation.

A. B. Carter, Inc. stocks several different types of spinning tapes to suit the varying machine designs and performance requirements for spindle drives. Tapes are available in any length and width with skived ends, pre-glued ends or can be made endless. Our patented joining system assures perfect end bonds with no variation in thickness or flexibility.

This portable device was designed specifically to produce high quality splices in our spindle drive tapes. This unit is available for 110V operation.

This mobile power cart was designed to offer safe and efficient use of the Cartabond in textile processing areas where power cords are inconvenient or difficult to use. This unit features a heavy-duty battery/inverter/charging system which allows the technician continuous uninterrupted use of the bonder throughout the shift without charging.

Specifically designed solution to produce high quality joins in spinning tapes. This nylon synthetic adhesive will activate at 300°F to permanently bond the tape.

Designed for quick-setting the bond after the tape is removed from the bonder.

A. B. Carter, Inc. supplies a wide range of flat and tangential belts for all types of power transmission applications. All belts can be custom made to your requirements, slit to width, cut to any length, and made endless or with skived ends.

A. B. Carter, Inc. offers a broad range of light weight conveyor belts for virtually any textile application. These belts are available with a variety of tension members and cover materials to meet the specific conveying requirements.

A. B. Carter, Inc. offers a full line of lifting straps for the textile industry. These straps are available in three basic types to suit the tensile strength requirements on the various textile processing machines. Our lifting straps can be supplied in roll form (100 ft. rolls) or with pre-cut lengths complete with fixing hardware already pre-assembled. These straps offer longer life as compared to chain products and are resistant to oil and grease.

| Textile Process | Equipment Manufacturer |

|---|---|

| Carding | Trutzchler, Rieter |

| Spinning | Ring Spinning – Zinser, Marzoli, Toyota, Rieter, Howa, Gaurdino |

| Open End Spinning | Schlafhorst, Rieter |

| Winding | Murata, Schlafhorst, Savio |

| Twisting & Direct Cabling | Volkmann-Saurer, ICBT, Verdol |

A. B. Carter, Inc. supplies a full line of high quality plastic roving and spinning bobbins. These are available in both steaming and non-steaming quality. Offered in engineering or non-engineering grade plastics and various surface finishes to resist rough handling, to improve winding efficiency and to provide a more defect-free yarn.

All ring spinning tubes are precision formed for concentricity at high speeds and are available in a choice of materials and colors to suit the customer’s requirements. A. B. Carter, Inc. has standard offerings available to fit Zinser, Marzoli, Rieter, Toyota, Howa and Saco Lowell spinning frames.

Manufactured for all major roving frames in lengths up to 450mm.

A. B. Carter, Inc. offers a complete line of handheld tension meters in basic analog and digital models for all yarns and process applications.

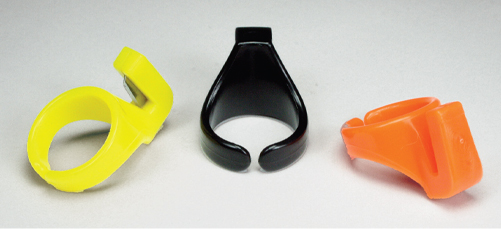

Designed to help install and remove travelers from the ring.

A. B. Carter supplies a range of critical parts used in the yarn formation zone of the ring spinning frame. All parts are made from the highest quality raw material manufactured to the proper hardness and smoothness in order to optimize the spinning process and yarn quality.

Designed for all textile applications, a durable cutting blade with safety guard to prevent operator injury.

Designed to assist in controlling the yarn tension in Two for One twisting applications to ensure the correct TPI (turns per inch) in the yarn meets the required specifications.

Designed for universal use on any machine and/or creel applications where precise yarn tension control is required.

Designed as a cost effective way to minimize yarn breaks caused by damaged cardboard or fiber tubes.